Powerful and Innovative Drilling Rigs for Many Applications

When it comes to drilling, there are many types of drilling rigs available in the market today, depending on a specific job. Despite the advances in drilling methods and equipment over the years, the concept of drilling is always the same – to drill a hole in the earth’s surface.

Due to advancements in technology, the drilling process has become more efficient, safe, and sustainable. The drilling rig equipment these days is more powerful, innovative, and versatile. They can perform efficiently and productively even in harsh environments and conditions.

This article will tackle more about the capabilities of new generations of drilling rigs, as well as some interesting things about this drilling equipment and how they were able to meet the demands of modern drilling.

New Generation Drilling Rigs – Qualities and Capabilities

Drilling is a complicated process that requires skill and top-of-the-line drilling equipment that can withstand the harsh elements and overcome the challenges.

Below are some of the qualities and capabilities of today’s rigs and platforms that help every driller meet the demand and challenges of the modern world.

Modern Rigs are Mobile

One of the top qualities of today’s rigs, whether land or offshore, is that they are mobile and can be transported from one location to another quickly and efficiently. Some rigs are either mounted on a track or trailer/truck for easy mobilization in a remote location.

Many drillers appreciate the fuel-efficient mobilization and reduced expense in maintaining these types of rigs, resulting in increased productivity and profit.

Uniquely Designed to Provide Custom Solution

Drill rig companies and manufacturers are dedicated to helping their clients in the drilling industry to perform better by manufacturing cutting-edge designs and unique equipment. They also develop solutions that meet project requirements using a complete project management methodology.

Improved Safety

New generation rigs were built with safety as a top priority. Due to the inherent danger and the risk of harming the environment, the safety features of drilling equipment have been improved through the years.

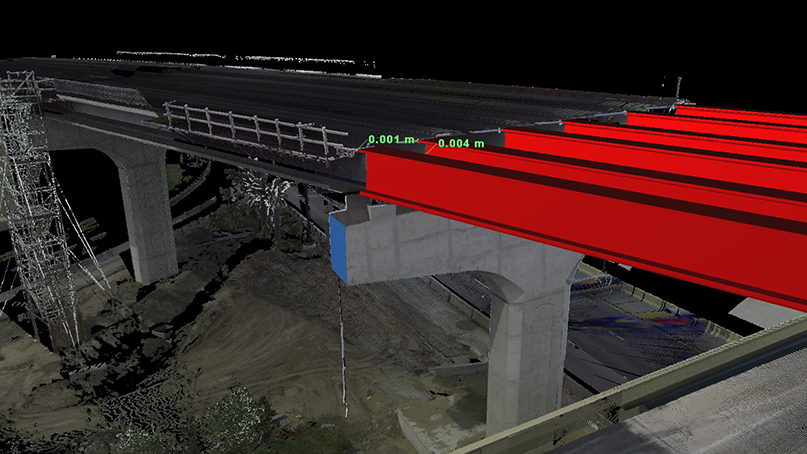

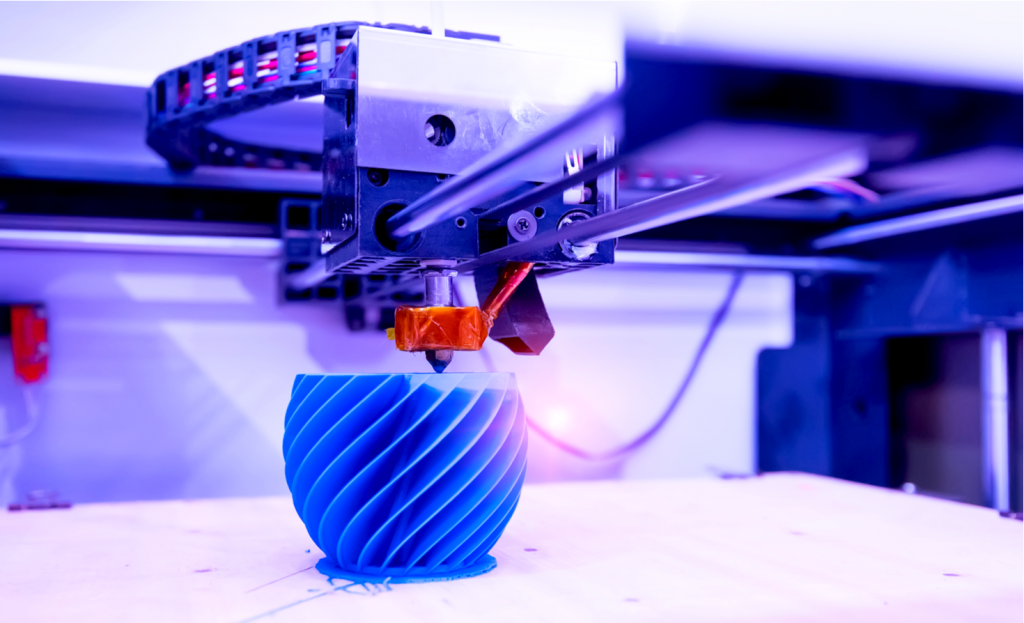

On top of stricter standards and comprehensive training, drill rig companies are also leveraging digital technologies such as artificial intelligence to enhance safety and efficiency and lower operational costs.

Equipped With the Latest Technologies and Innovations

Advancement in technology continues to transform modern rig drilling equipment. The new generation rigs are equipped with the latest technologies and innovations to improve safety, performance and productivity.

Continued research is being done to ensure that the drilling equipment is able to keep up with the demand and challenges of modern drilling.

Versatile and Sustainable

Manufacturers of drilling equipment are now offering drilling machines for different applications while promoting safer, cleaner, and sustainable drilling operations. These leading manufacturers also focus on helping drillers to optimize their whole processes with a vision of creating a more sustainable future for the entire drilling industry.

Summary

Drilling is a complicated and risky business. Thankfully, plenty of dealers and manufacturers offer new-generation drilling rigs that you need to take your business to the next level.

Be sure to consider these factors and the qualities of modern rigs in your buying decision. Also, it is crucial to set the right budget. Otherwise, you might limit yourself from the benefits you should get from your drilling equipment.

Lastly, keep in mind to purchase your drilling equipment from a reputable manufacturer to ensure that you will get excellent customer service during the buying process and after-sales support.

More importantly, you would like to know that this company will be around for a long time when you need to repair and keep your drilling equipment working for the years to come.

Powerful and Innovative Drilling Rigs for Many Applications Read More »