Overlooked Benefits of 3D Scanners

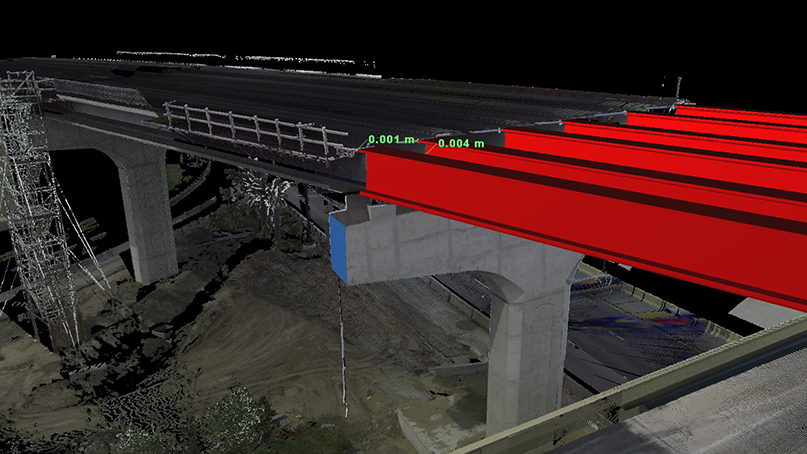

3D laser scanning is a crucial innovation development in the construction sector. Considering that showing up on the scene nearly 20 years back, the tool has allowed building specialists to capture exact site problems and as-built details more quickly and confidently.

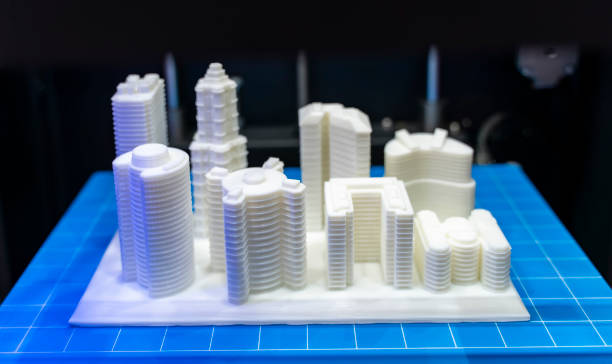

3D laser scanning makes it much easier to document and visualize current as-built conditions when used for improvement and redesigning jobs. The information can be used to develop as-builts when they do not currently exist and to develop accurate 3D models and contrast illustrations or documentation versus as-built problems.

Benefits of 3D Scanners

Decreases Interruptions

When a construction project begins, your group must scope, action, and capture the present conditions and details of the website. For restoration and renovating projects, there may be people living or operating in the area that you need to suit and work around. While it’s a required part of the work, your existence can seem like a breach. If you’re still using inefficient hand-operated techniques to take measurements or if you need to return numerous times to see to you have recorded all the details you need, your effect on the residents of the space is felt all the more.

In addition to making it simpler to record current job information, 3D scanning limits the impact of your deal with owners and the passengers of their centers. As a result of its small capacities, scanning can be done quickly with minimal or no disturbance to those working in

or inhabiting the room. You can inconspicuously and unobtrusively gather comprehensive as-built problems while staff members, locals, and others are present on the website.

Boosts Safety and Security

On building and construction job sites, any variety of harmful conditions and safety concerns can place your group at risk. Supported by the rate and power of 3D laser scanning, you can improve your team’s security by minimizing the time they are exposed to recognized risks or potentially threatening atmospheres. You can obtain accurate data promptly and also without having to invest extreme time on a harmful job site.

The information returned from 3D scanners can additionally improve safety by allowing you to pre-plan your job and also identify or else unidentified hazards and also dangers in existing frameworks. You can avoid placing your workers at unneeded threats by identifying future problems before they materialize issues. The scan data can even be used in safety and tools training. An unfamiliar job site is an ordinarily risk-prone atmosphere. However, 3D scans enable you to give a sensible sneak peek of the room, making it less complicated for workers to acclimate when they are actually on the website.

Almost Always Spends for Itself

The security benefits alone can make 3D scanning a straightforward decision– and also an invaluable one. However, as a tool, 3D scanning additionally has prevalent application potential that makes it possible to use it in more methods than you may realize– as well as make it accessible to more individuals in your group than you might have thought feasible.

Brand-new 3D laser scanners are entering the marketplace that does not require unique training and can be promptly discovered by various architecture, design, and building experts in the field. You can use a single scanning solution throughout different practical locations, allowing each group to obtain the necessary information when required. As well as, you can rapidly get exact check information to share across teams, helping with better partnership and more vital interaction.

Overlooked Benefits of 3D Scanners Read More »