How to Keep Your Waterjets Cutting Machine Area Spic and Span Even amid a Production Schedule?

Everyone knows that the use of waterjets cutting machines in handling various material cutting or slicing needs can be very advantageous. However, there is a downside to it. Water jet cutting has a notoriety for being a very messy operation.

The moment that pulverized abrasive gets into contact with water, it forms “muck”. This sometimes runs the risk of flying out of the tank wrought out by the cutting process itself.

This explains the reason why the vast majority of fabricators would want to have their laser cutting systems at a safe distance, away from water jet cutting activities, to keep them safe and secure from the risk of possible damage.

A lot of metal fabricators choose to contend with the topsy-turvy byproducts of the waterjet cutting activities. Nevertheless, they must know that this would not have to be the case.

A Clean Waterjet Cutting Area-Install and Surround the Tank with Shields

In using a waterjet cutting machine system to cut metal, it runs the risk of water spray itself being kicked back at you.

The jet may hit the top slats, triggering a kickback, or it may hit the bottom slats, and cause a load of turbulence, which will have water shoot over the edges of the tank.

With a height of about 2 to 3 feet, they can easily stick to the sidewalls of your tank, keeping the sprays contained within. The cost-effective alternative to transparent plastic shielding is metal shieldings. You can buy them online, or make some yourself.

Do not forget that operators have a natural tendency to lean more on the use of clear shields. It’s because it lets them see through the tank easily and thus know right away what is happening right there and then. The shielding that is in close range or proximity to the control station needs to be transparent.

Consider Cutting Underwater

Cutting underwater is a great way to boost the cutting process because it will help you keep things contained and clean. The piercing method has done underwater still creates spray, but not everything will be able to escape the tank while the system is carrying out its work. Besides, cutting underwater will minimize noise.

Seasoned waterjet cutting machine operators who, through the years, have become so well versed in slicing above the water line have grown to like it because it makes it possible for them to see the cutting process more clearly.

If you decide to give underwater cutting a shot, see to it that you have a solid job program. This will take away the possibility of tip-ups, and thus, for that reason, you will not have to worry about it. It works to your advantage not to run a program and have it as a first-time underwater cutting job.

Treat the Waterjet Tank as Though It Were a Car

Rinse off the machine and hose it down at the end of the day. Make this a habit to prevent the muck that gets kicked out of the tank and becomes trapped in the tank from drying out. If that happens, it will become even more challenging to eradicate.

If at all possible, rinse the tank after each use. Fill a bucket with soap or detergent solution and use a broom to clean your unit. Or you can also opt to run a scrub brush using a stick. This is also considered a practical way to keep it squeaky clean.

If At All Possible, Use Only Water In Cutting

Waterjet cutting necessitates the use of abrasives for the majority of sheet metal jobs. When working on a project that involves the use of metal, the use of abrasive particles would be necessary. However, if you’re cutting an object that will let you forego the use of abrasives, it will take away the creation of dust and muck.

It also reduces the amount of used abrasives, which is good if you are so keen on saving more money.

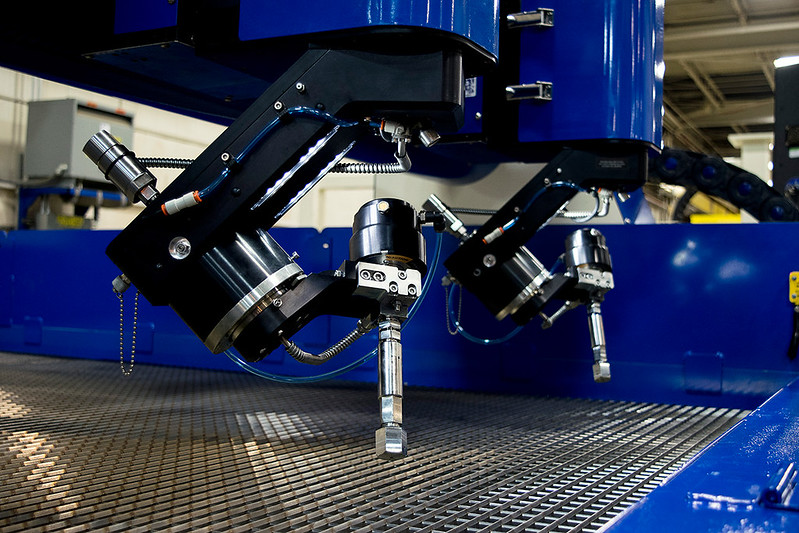

Think About Using Flood Nozzle

The job of a flood nozzle is to produce a continuous curtain of water all around the jet stream, which is most helpful in containing the kick-back.

The work of the flood nozzle is to aid in the frosting of the material’s edge after it was cut through while cutting glass or a polished material.

Fabricators frequently take advantage of plastic or aluminum shields and surround the waterjet stream with it. This measure will help in keeping the mess right inside the tank.