3D Printing Brisbane: Accelerating Automotive Design and Efficiency

The success and growth of every business greatly depend on constant innovation and staying ahead of the competition. It is particularly true in almost all major industries, including the automotive industry.

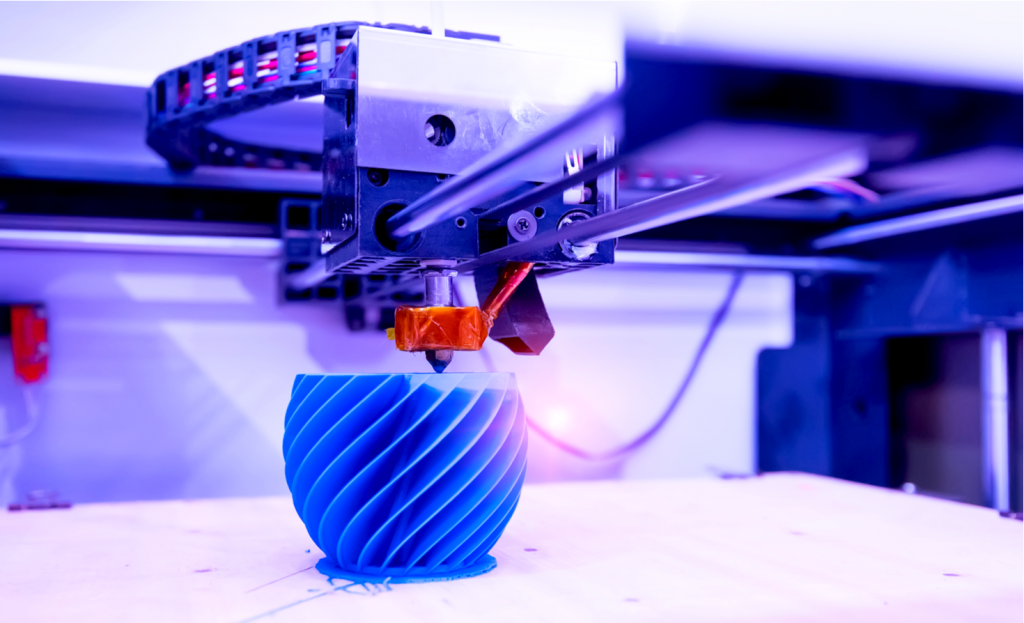

Today, leading automotive manufacturers are integrating 3D Printing technology in their production lines to accelerate the product development stage and reduce resources, such as time, money, and energy.

With the guidance and expertise of 3D Printing Brisbane, the insurmountable challenges faced by traditional manufacturers in adopting and embracing this digital technology have helped them successfully navigate this dynamic market.

In this article, we’ll wade into the different ways 3D printing is helping and benefiting automakers in accelerating their product design, efficiency, and production processes.

The Benefits of 3D Printing Brisbane for the Automotive Industry

1. Design Innovation and Optimization

Creating complex and intricate automotive designs using the traditional method is a major challenge in the automotive industry.

But with 3D printing, automotive manufacturers can create complex designs, customized functional parts, and units for their discerning customers.

This technology can also help design engineers to create lighter vehicles with optimized weight and performance by combining 3D printing and generative design.

2. Streamlined Parts Consolidation

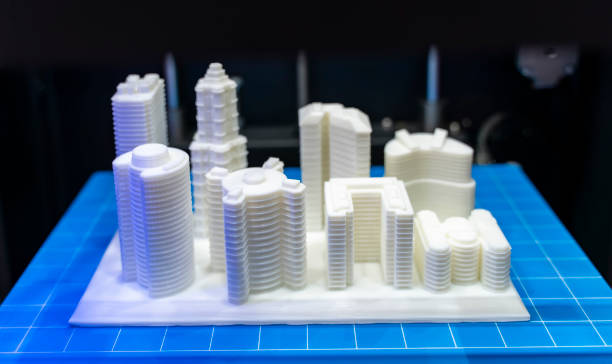

Another significant advantage of 3D printing is the creative freedom it provides engineers during the design stage, which is impossible to achieve in the traditional method.

With part consolidation, engineers can integrate multiple parts into a single component in the design stage and reduce material usage and the costs and time of parts assembly.

3. Mass Customization

3D printing allows original equipment manufacturers (OEMs) for mass customization of vehicles based on their client’s needs in more flexible and cost-effective ways.

Specialty car manufacturers are leaning toward 3D printing technology to produce personalized parts for both the interior and exterior parts of the vehicle. In doing this, the luxury segment of the industry can entice their customers with a better experience and stay ahead of the competition.

4. Custom Tools

When it comes to production lines, efficiency is the top priority of most automotive manufacturers. And to achieve these, manufacturers employ cutting-edge technologies to customize tools and fixtures to improve and simplify the process.

Although prototyping is the key application of 3D printing within the automotive industry, using the technology for creating reliable custom tools is frantically increasing.

3D printing is the go-to technology of manufacturers in creating these custom tools and extensions for three reasons; it’s cheaper, fast, and more ergonomic in design.

5. Spare Parts

Automakers are also benefitting from 3D printing technology in creating or replicating on-demand spare parts in a variety of materials, quickly and easily.

With 3D printing, manufacturers can avoid the high inventory cost of storing spare parts and offers cost-effective production, leading to an enhanced delivery time and a simplified supply chain.

Summary

The transformative applications of 3D printing to the automotive industry are truly remarkable in ways never possible before.

The accelerating innovation and competitive advantages of this technology drive automotive production to become a billion-dollar business in years to come.

3D Printing Brisbane: Accelerating Automotive Design and Efficiency Read More »