When you are in charge of overseeing the cutting of materials for various kinds of construction and manufacturing applications, and for the very first time you tried the CNC plasma cutting table, you will realize that nothing will help you get the job done right the moment that you have had your hands on it.

Plasma cutting machines are automated. You operate them with the help of a computer system. This explains the reason why they have a high level of precision, each and every time a single time they are used. A CNC machine operator will provide the necessary geometric dimensions to the computer system, which is linked to the CNC cutting equipment, and after which the system will cut your material accordingly.

It is not just their high level of precision that this material cutting system takes high pride in, but these machines also boast of their customizable functionalities. This allows for CNC operators to change the settings accordingly, based upon the specific requirements of a particular project they are handling

What is Plasma Cutting?

Plasma. This is the term by which the scientific community named electrically charged gases. Comprised of charged particles, there are a number of wonderful things that plasma can do but gases won’t deliver. Like for instance, plasma can conduct electricity.

When used as a cutting tool, plasma torches are capable of shooting plasma at such an amazing velocity towards the electrically-conductive metal that you want to cut. This will result in the production of an extremely high heat — to the rising temperature of around 20,000 degrees Celsius. This is equivalent to 36,000 degrees Fahrenheit. And this is so hot, it is 3 times hotter than the surface of the sun.

With temperatures so high and powerful it will easily light up the solar system and seamlessly cut through metal to a maximum of an inch thick. After this, there is a need for a second spray of gases. This will help blow the molten residue away from the cut. If you will employ instead of the use of the mechanical method of cutting, such as ordinary torches and saws, it will take you a significant amount of time to complete the same cut.

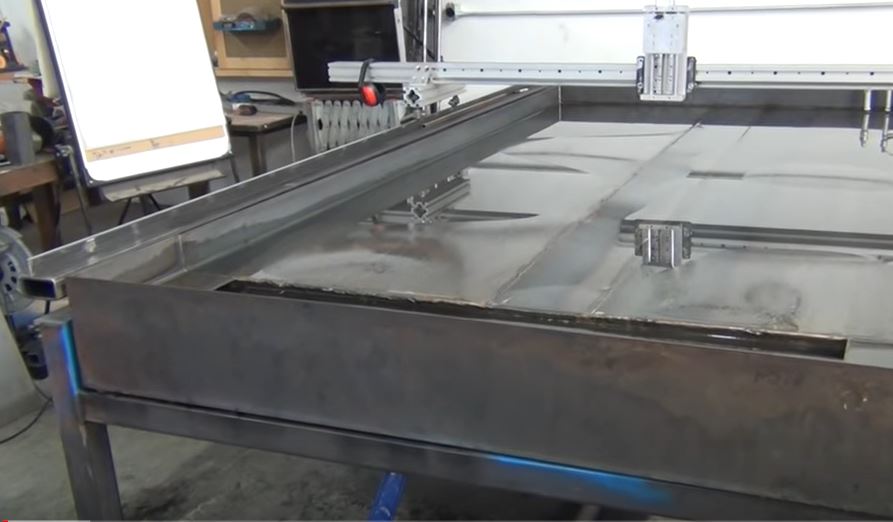

While you are free to use instead hand-held plasma cutting system as your method of choice, we highly recommend the use of a cutting table to help facilitate a more efficient way of fabricating your metal cutting projects. The plasma torch can be anchored in place to the table with the help of a hydraulic arm. This would be capable of doing a 360-degree turn or move along the x, y, and z axes.

You will enjoy the following benefits when you use a fabricator that comes with a CNC cutting table.

- Computer Controlled Precision

The CNC or computer numerical control interface that is existing between the plasma cutter servomotors and the electronic brain signifies seamless robotic precision with every single cut you make. Where the human element of control on the cutter is really of no help, the CNC cutter system will deliver you with repeatable and refined cuts, every single time.

Moreover, the CNC module and the CAD (computer-aided design ) program would work together, provided that your enlisted fabricating team made a wise move of investing in a higher-end model, your specifications would easily translate to the plasma cutting table. This level of ease of transfer is tantamount to reduced probability for errors to occur.

2. Rapid Fabrication

If your project is advancing and making good progress, rebar fabrication or delays in erecting your structural steelwork is the last thing that you wish to happen. Provided that your supplier knows exactly how to make good use of a CNC plasma table, the process of assembly has a good chance of advancing even more quickly as opposed to the use of traditional systems of cutting.

Abating the likelihood of the occurrence of human error or mistake and accelerated cutting time, the steel fabricating team you chose to partner with should be more than capable of processing your steel/metal cutting project well within your designated schedule.

3. Fast Delivery

Needless to say, your partner fabricating team should be able to deliver your order lightning fast with the amount of time that has been sliced off production. With your required materials on standby in your worksite, your structural and concrete framing timetable is likely going to stay on track. Provided that everything will go on smoothly and seamlessly according to plan, you will likely stand a greater chance of accomplishing things on time for your client.