Does Waterjet Cutting Machine Cut Through Steel?

A waterjet cutting machine is a modern piece of cutting equipment. They are used in many industries today and can be seen in many different machine and fabrication shops in the country.

As one of today’s preferred material cutting tools, they can efficiently cut metal parts just by the use of a high-pressure jet of water.

Water itself cutting through tough material like metal indeed sounds pretty amazing but it is true. Provided that the right elements are there and water is made to flow fast enough and make it reach a point that it can cut through metal.

Waterjet cutting machines are analogous to a power washer wand. This can be usually seen in a local car wash and chances are high that you might have seen one.

If you want to understand how water jet cutters work, you can just try to observe how power washers are run and that will let you know exactly the mechanics of waterjet.

The waterjet technology is actually 30 times better and more powerful than the power washers we see. If you let these two machines run side by side and observe, you will see how poor a power washer would fare to how a waterjet cutter will perform.

The Secret to the Power of Waterjet Cutters

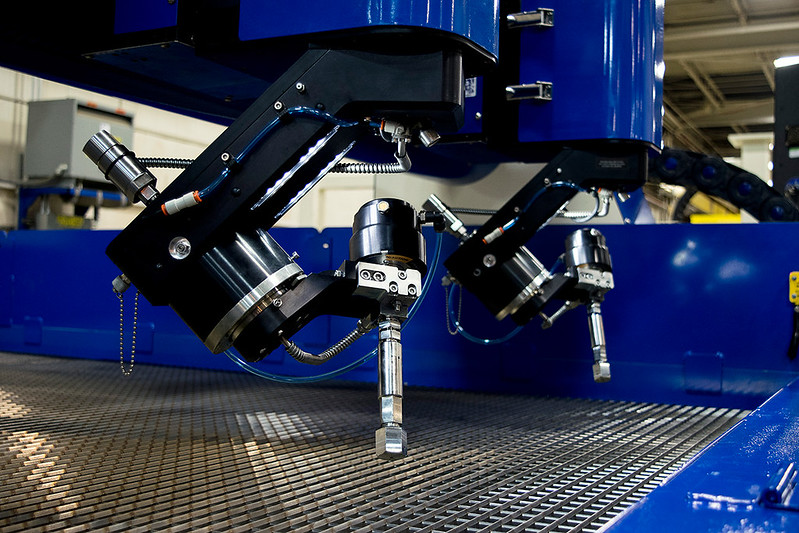

The secret to the cutting power of a waterjet cutting machine lies in the strong and coherent spray of water. Waterjets can cut through tough objects such as metal because it channels the water spray through an extremely narrow jeweled nozzle at such high pressure. By this measure, the water spray will remain coherent.

Unlike the traditional metal cutters, a waterjet machine will never get dull. There is also no chance that it will overheat.

The very first time that waterjet technology was first used can be traced back to 1852. Low-pressure water jets were popularized then and were used primarily for gold mining. Come the 1900s, hot water jets and steam was introduced as a better alternative for cleaning purposes.

It is only in the latter part of the 1960s that high-pressure waterjets were first used, but it took another 10 years more before the industry initiated the use of waterjet technology to help address its need for better, faster, highly efficient material cutting applications. The use of abrasive materials in waterjet (abrasive waterjet) which has something to do with adding garnet particles in the water came only in the 1980s.

Waterjets can cut through the following tough materials:

- Granite

- Metal

- Marble

- Stone

- Wood

- Plastic

- Stainless steel

Waterjets are so powerful that they can even cut through a “sandwich” of different materials to a maximum of 4 inches thick. The cutting process itself is relatively heat-free and dust-free and, unlike other conventional material cutting methods, waterjet technology will not produce any foul-smelling odor or fumes.

Waterjet system alone, sans any abrasives, is ideal for cutting “softer” materials, whereas the abrasive type of waterjet is intended instead for cutting harder, tougher objects. The process of actual cutting is often carried out underwater, to lessen noise and splash. The purpose of faster feed rates is to keep the jet of water from cutting through the object all the way.

As for the water pressure, typically they would range between 20,000 and 55,000 psi. The high pressure being applied to the water will force it through a 0.010” to 0.015” hole or orifice in the cutter head.

Does Waterjet Cutting Machine Cut Through Steel? Read More »